By Dr. Klaus M. Blache, Univ. of Tennessee, Reliability & Maintainability Center Reliability-centered maintenance (RCM) is a process designed to establish the safe minimum level of maintenance for each piece of machinery/equipment in a facility. It’s concerned with maintaining functionality of individual components in an entire system. Many companies are aspiring to do it. Others are doing […]

Final Thought: RCM — Great Tool or Ravenous Monster?

“Pit Crews” Keep Snacks On Track

High-performance machines require highly skilled professionals who use a race-car team approach to maintenance and reliability at Frito-Lay’s largest North American manufacturing facility. By Michelle Segrest, Contributing Editor The one million-sq.-ft. Frito-Lay manufacturing facility in Perry, GA, operates like a well-oiled, high-speed race-car track. The operations teams drive the machines, but it’s the 100 maintenance professionals […]

Monitoring Slow-Speed Bearings With Ultrasound

This maintenance professional’s account of his site’s experience with ultrasound technology lays out details that can help others. By Ron Tangen, CMRP, Dakota Gasification Co. Dakota Gasification Co. (DGC), a for-profit subsidiary of Basin Electric Power Cooperative, Bismarck, ND, owns and operates the Great Plains Synfuels Plant, a coal gasification complex near Beulah, ND. The plant produces […]

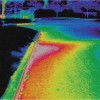

Use Infrared to Detect Underground Leaks

Suspect a buried leak? Thermography can help you find it. By James Seffrin, Director, Infraspection Institute Leaks are a common problem with underground piping systems. Under the correct conditions, infrared thermography can help you detect evidence of leaks from buried systems that carry hot or cold product. This set of images shows a thermal pattern created […]

Schneider Electric Furthers IIoT Evolution

“The Industrial Internet of Things [IIoT] is an evolution, not a revolution,” was the lead statement at the Schneider Electric SPS Nuremberg show in Nuremberg, Germany, Nov. 24, 2015. To support that claim, Clemens Blum, Schneider’s executive vice president of industry business, referred to the description of a Schneider 1999 Computerworld Smithsonian Award that talked […]

Consider The Common Cause Method

What appear to be stand-alone issues in different areas of a plant may actually have some things in common. Rooting out those factors is the only way to prevent such problems from recurring. By Randall Noon, P.E. Common-cause analysis is a relatively straightforward root-cause method. Sometimes referred to as “determining the cause of causes,” it’s used […]

My Take: Connecting Your Enterprise — Leveraging the Internet of Things

By Jane Alexander, Managing Editor This month’s cover asks “What’s Trending Now?” My take is that the “Internet of Things (IoT)” is one of the hottest topics out there, especially among the suppliers of technologies for consumer, commercial and industrial applications. Alas, among industrial end-users, the IoT may be one of the least understood trends. […]

Preventing Impending Equipment Failure Earlier

Advanced-pattern-recognition technology adds a powerful predictive component to your reliability toolbox. By Jane Alexander, Managing Editor Improving reliability metrics has long been among the top priorities of plants and other physical asset-intensive organizations. Plant managers, engineers and technicians continually work to ensure that equipment will efficiently operate for as long as safely possible. Proper maintenance […]